Wire-O Binding stands out as a versatile and popular technique in the dynamic realm of book printing services. This guide aims to unravel the intricacies of Wire-O Binding, shedding light on its definition, advantages, applications, and the process involved.

Understanding Wire-O Binding

Definition and Key Characteristics

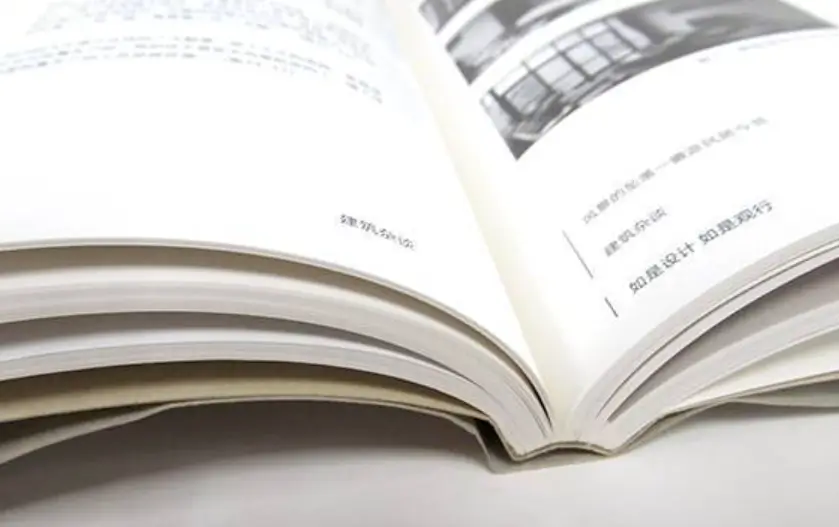

Wire-O Binding, also known as twin-loop binding or double-loop binding, involves securing the pages of a book by threading a metal wire through punched holes along the critical edge. This method ensures a sturdy yet flexible binding, allowing runners to lay flat for optimal readability.

Advantages and Unique Features

One of the standout features of Wire-O Binding is its ability to provide a polished and professional look to various printed materials. Wire-O Binding offers durability and a sleek appearance, whether for manuals, catalogs, or presentations.

Applications and Ideal Use Cases

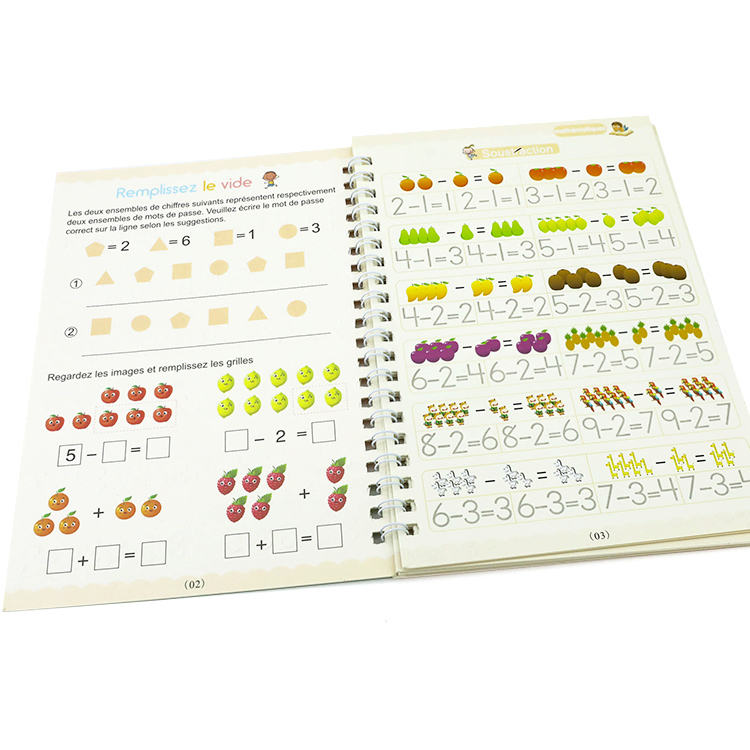

Wire-O Binding services are particularly well-suited for projects that require a contemporary and stylish finish. Its flexibility makes it ideal for various materials, from instructional manuals to promotional materials.

Common Questions and Concerns

Addressing Cost Considerations for Wire-O Binding

One common question when considering Wire-O Binding services is related to cost. While the initial investment may be slightly higher than other binding methods, the long-term benefits often outweigh the expenses. The professional look and enhanced durability contribute to the overall value.

Durability and Longevity of Wire-O Bound Books

The durability of Wire-O Binding is a critical factor that sets it apart. The metal wire ensures that pages stay securely in place, minimizing wear and tear over time. This makes it an excellent choice for materials that will be frequently referenced or handled.

Customization Options: Tailoring Your Book with Wire-O Binding

For those seeking unique and customized printing solutions, Wire-O Binding services offer ample opportunities for personalization. From choosing cover materials to wire colors, clients can tailor their projects to meet aesthetic and branding requirements.

The Wire-O Binding Process

Now, let’s delve into the intricate process of Wire-O Binding, exploring the steps involved in bringing your printed materials to life.

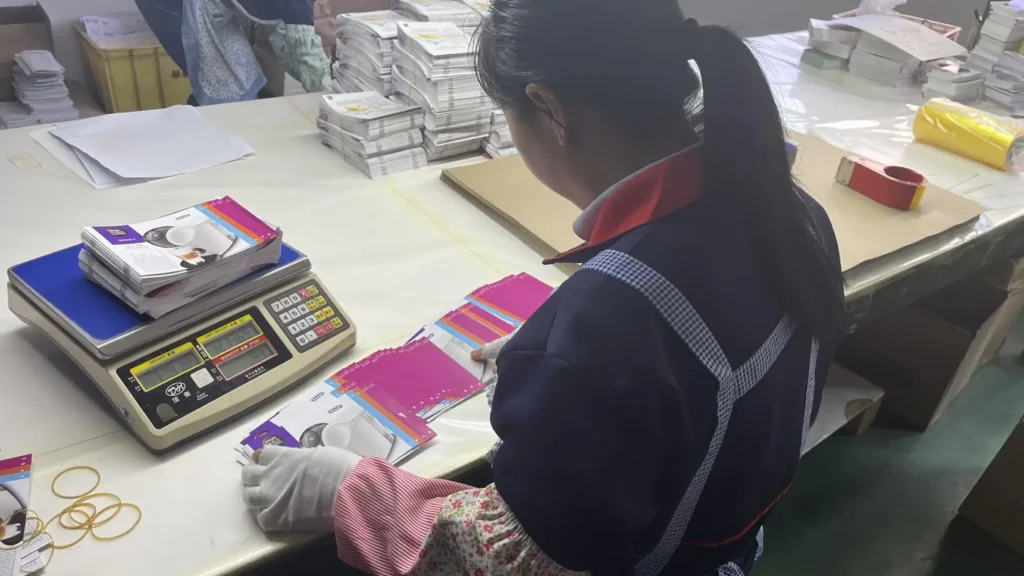

Step 1: Preparation and Collation of Pages

Before the Wire-O Binding process begins, meticulous preparation is essential. Pages are collated in the desired order, ensuring the final product aligns seamlessly with the intended design and content flow.

Step 2: Punching Holes in Prepared Pages

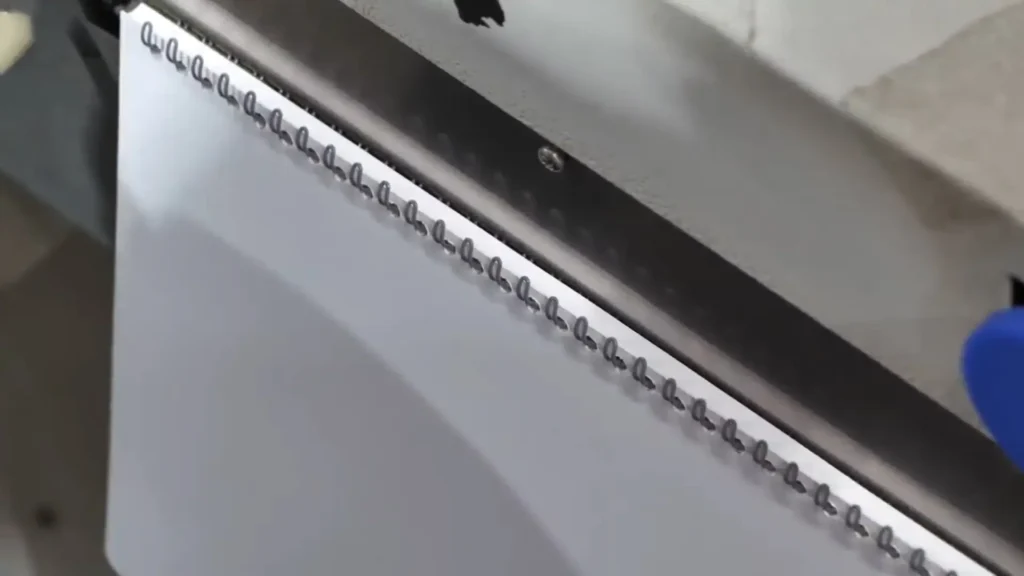

Precise hole punching is a critical step in Wire-O Binding. The prepared pages are carefully aligned and punched along the binding edge. The number and placement of holes depend on the project’s specific requirements.

Step 3: Inserting and Closing Wire-O Binding Coils

Once the holes are punched, the metal wire coils are inserted through the prepared holes. The diameter of the wire and the pitch between loops contribute to the overall stability and flexibility of the bound pages. Advanced machinery ensures a secure and consistent binding.

Step 4: Quality Control Measures in Wire-O Binding

Quality control is paramount in Wire-O Binding services. Each bound book undergoes a thorough inspection to ensure the pages are securely fastened, the wire coils are appropriately closed, and the overall presentation meets the highest standards.

Step 5: Ensuring a Professional Finish

The final step involves trimming any excess wire and ensuring the bound book has a clean and professional finish. This attention to detail enhances the overall aesthetic appeal of the product, making it ready for distribution or display.

Wire-O Binding vs. Other Binding Techniques

Now that we’ve demystified the Wire-O Binding process let’s compare it with other popular binding techniques, highlighting its unique advantages.

Comparative Analysis with Perfect Binding

While suitable for specific projects, perfect binding lacks the sturdiness and lay-flat capability that Wire-O Binding offers. The wire in Wire-O Binding allows for greater flexibility and durability, especially in materials requiring frequent handling.

Pros and Cons of Wire-O Binding Compared to Saddle Stitching

Wire-O Binding provides a more professional and polished appearance compared to saddle stitching. While both methods suit various projects, Wire-O Binding is preferred for materials requiring a sophisticated finish and extended durability.

Unique Advantages of Wire-O Binding Over Spiral Binding

Wire-O Binding surpasses spiral binding with a sleeker and more secure appearance. The double-loop wire ensures a more professional look, making it an excellent choice for presentations, manuals, and promotional materials.

More Bookbinding Tips-Exploring Various Bookbinding Techniques: A Comprehensive Guide

Expert Tips for Optimal Wire-O Binding Results

Achieving the best results with Wire-O Binding involves thoughtful design and adherence to best practices. Here are some expert tips to enhance your Wire-O Binding projects:

Design Considerations to Enhance Wire-O Bound Books

- Margin Planning: Ensure sufficient margin space to accommodate the binding without compromising text or images.

- Cover Design: Utilize the cover space to make a lasting impression. Wire-O Binding allows for creative cover designs, including custom graphics, logos, and text.

- Consistent Font Sizes: Maintain a uniform font throughout the document to create a polished and professional look.

Maximizing Creativity within Wire-O Binding Specifications

- Color Coordination: Choose wire colors that complement or contrast with the cover design to add visual interest.

- Paper Selection: Experiment with different paper textures and weights to enhance the tactile experience of the bound book.

- Incorporate Inserts: Take advantage of the binding method to include inserts or fold-out pages for additional information or visual impact.

Addressing Potential Challenges in the Wire-O Binding Process

- Careful Hole Alignment: Ensure precise hole alignment during punching to prevent wire insertion issues.

- Quality Wire Selection: Opt for high-quality wire materials to avoid rusting and maintain the longevity of the bound books.

- Professional Printing Services: Collaborate with reputable book printing services specializing in Wire-O Binding to ensure a seamless and professional outcome.

Industry Standards and Certifications in Book Printing Services

Importance of Working with Certified Printing Services

Choosing a printing service with recognized certifications, such as ISO 9001 and FSC (Forest Stewardship Council), ensures a commitment to quality, environmental responsibility, and ethical business practices.

Adherence to Quality and Environmental Standards in Wire-O Binding

Certified Wire-O Binding services prioritize using eco-friendly materials and adhere to strict quality control measures, guaranteeing that your projects meet or exceed industry standards.

Industry Recognition and Awards for Wire-O Binding Excellence

Look for printing services that have received industry recognition or awards for their excellence in Wire-O Binding. This indicates a track record of delivering exceptional results and customer satisfaction.

Conclusion: Unleashing the Potential of Wire-O Binding Services

As we conclude our comprehensive guide, it’s evident that Wire-O Binding services offer many advantages for those seeking professional and durable book printing solutions. Let’s recap the key takeaways and invite you to explore the excellence of Wire-O Binding for your next project.

Recap of the Benefits and Steps of Wire-O Binding

- Durability and Professionalism: Wire-O Binding ensures a durable and professional finish, making it ideal for a wide range of materials, from manuals to promotional materials.

- Lay-Flat Capability: The unique double-loop design allows pages to lay flat, enhancing readability and user experience.

- Customization Options: Wire-O Binding services provide ample opportunities for customization, allowing you to tailor your projects to meet specific aesthetic and branding requirements.

- Expert Tips for Success: Consider design elements, maximize creativity within specifications, and address potential challenges to ensure optimal results with Wire-O Binding.

- Industry Standards and Certifications: Collaborate with certified printing services that adhere to quality and environmental standards, ensuring a responsible and ethical approach to book printing.

Inviting You to Explore Wire-O Binding Excellence

Now armed with a deeper understanding of Wire-O Binding, we invite you to explore the excellence of Wire-O Binding services for your book printing needs. Whether you’re working on manuals, catalogs, presentations, or promotional materials, Wire-O Binding can elevate your projects’ visual appeal and durability.

Choose a printing service that specializes in Wire-O Binding and holds industry certifications, guaranteeing a commitment to quality, environmental sustainability, and overall excellence.

For inquiries and to experience the unmatched professionalism of Wire-O Binding, reach out to our dedicated team of experts at Tina Hong Printing, where we bring your ideas to life with precision and finesse.

Thank you for embarking on this journey of Wire-O Binding demystification with us. We look forward to being your trusted partner in bringing your printed materials to the next level.

Stay tuned for more insights and guides from Tina Hong Printing.