Introduction

In book production and publishing, achieving high-quality bindings is essential for the durability and aesthetic appeal of the final product. Smyth Sewn Binding is a superior technique that ensures strength and elegance in bookbinding. In this comprehensive guide, we will delve into the intricacies of Smyth Sewn Binding and how it can benefit your book printing services.

What is Smyth Sewn Binding?

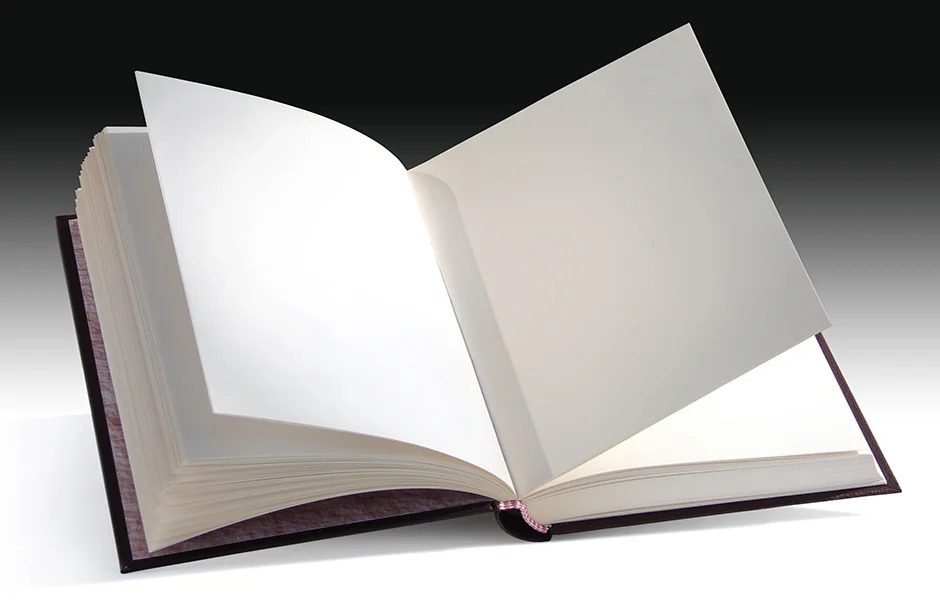

Smyth Sewn Binding, also known as section sewing or Smyth sewing, is a meticulous bookbinding technique that involves sewing together folded sheets or signatures. This method is renowned for its ability to create exceptionally durable and aesthetically pleasing books. Unlike other methods like perfect binding, Smyth Sewn Binding ensures that pages open flat and securely.

The history of Smyth Sewn Binding dates back to the 19th century when David McConnell Smyth patented this innovative technique. Over the years, it has evolved and perfected, making it a top choice for book printing services seeking superior quality and longevity.

Advantages of Smyth Sewn Binding

Durability and Quality

One of the standout advantages of Smyth Sewn Binding is its unparalleled durability. The sewn binding creates a robust structure that can withstand the test of time, making it ideal for books that will be frequently used or handled. It prevents pages from falling out, ensuring the book remains intact even after extensive use.

Lay-Flat Page Opening

Unlike other binding methods, which can cause books to snap shut or pages to curl, Smyth Sewn Binding allows books to lie flat when they are opened. This feature is especially valuable for textbooks, manuals, and any publication where readers need easy access to content without the annoyance of pages constantly turning or closing.

Applicability to Different Types of Publications

Smyth Sewn Binding is highly versatile and can be applied to various publications, including hardcover books, softcover books, magazines, journals, and more. Whether you are a book printing manufacturer, a magazine publisher, or need specialized bookbinding services, Smyth Sewn Binding can cater to your specific requirements.

Applications of Smyth Sewn Binding

Smyth Sewn Binding’s versatility extends to a wide range of publications, making it an attractive choice for various industries. Here are some typical applications:

1. Book Printing Services

Book printing services benefit significantly from Smyth Sewn Binding. Whether you’re printing novels, reference books, or coffee table books, this binding method ensures that your books look professional and withstand the test of time. Readers will appreciate the quality and durability of Smyth Sewn Binding, enhancing their overall reading experience.

2. Magazine Printing

Magazine publishers often opt for Smyth Sewn Binding when they want to produce high-end, collectible magazines. This method ensures that pages won’t come loose, and magazines can lay flat, allowing readers to enjoy every page without struggling to keep it open. The luxurious feel of Smyth Sewn magazines can also attract a discerning audience.

3. Journal Binding

Academic journals, scientific publications, and research papers require a binding method for frequent use and referencing. Smyth Sewn Binding is a perfect choice for these types of publications. It not only provides durability but also lends a professional appearance, which is crucial for scholarly works.

4. Customized Publications

For unique and specialized projects, Smyth Sewn Binding offers customization options. Whether you’re producing limited edition art books, portfolios, or niche publications, this method allows you to tailor the binding to your specific design and content requirements.

You can cater to a diverse clientele seeking high-quality, long-lasting publications by offering Smyth Sewn Binding services.

The Process of Smyth Sewn Binding

Materials and Tools

- Types of Paper or Materials Used for Pages: Choosing paper or materials is crucial for the final product’s quality. Different paper types can be used depending on weight, texture, and intended use.

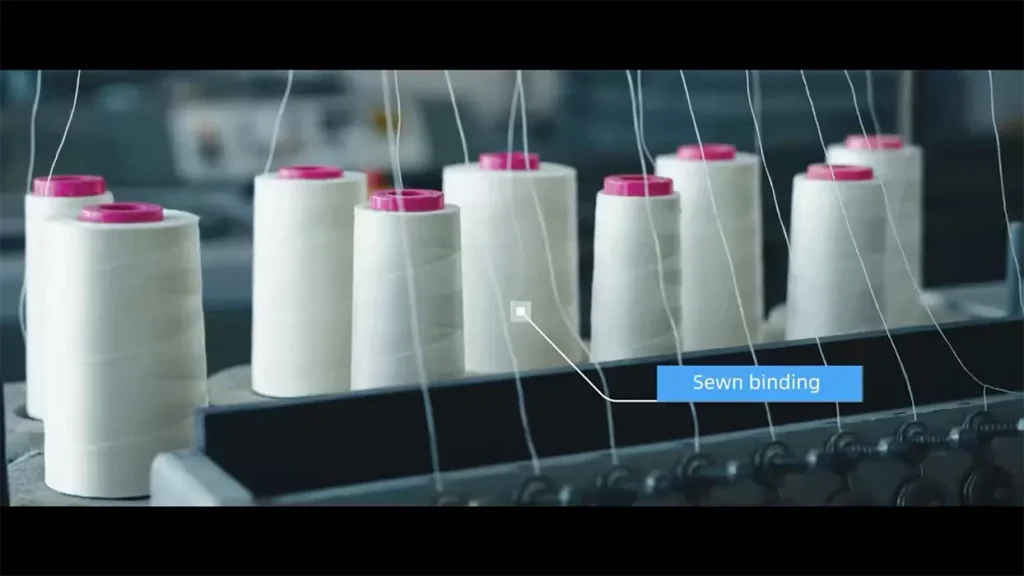

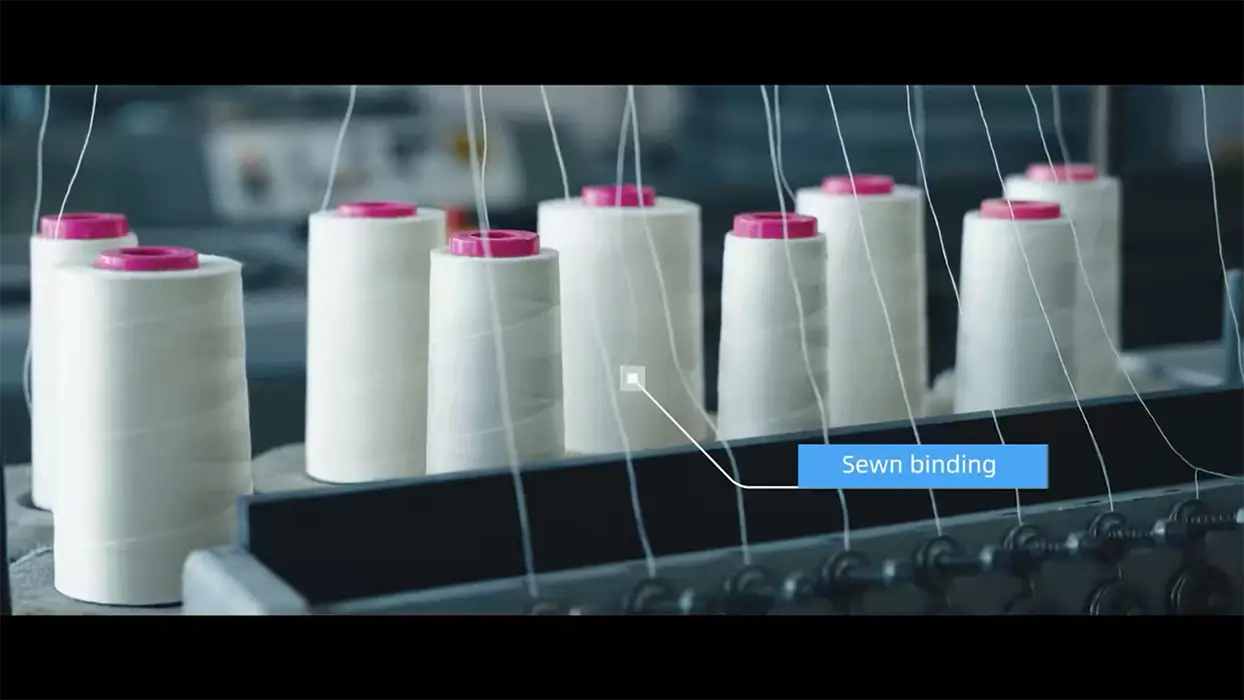

- Sewing Thread and Needles: High-quality sewing thread is essential for a strong and lasting binding. Various types of needles are used for different materials and thicknesses to ensure precision in stitching.

- Cover Materials (if Applicable): If your publication requires a cover, materials such as cloth, leather, or specialty covers can be chosen to enhance the visual appeal and protection of the book.

- Binding Equipment and Machinery: Specialized binding equipment and machinery are used in the Smyth Sewn Binding process. These machines are designed to handle the precise sewing and assembly required for this technique.

Technical Steps

1. Preparation of Pages:

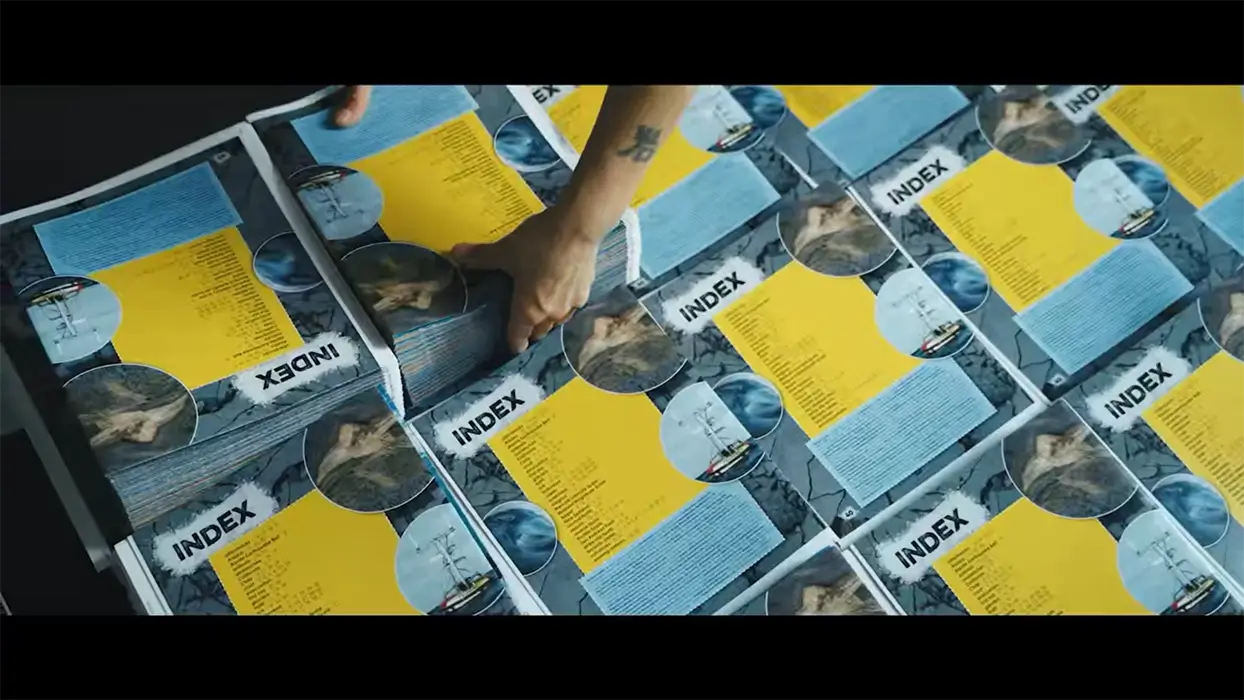

- Cutting and Trimming: Pages are cut and trimmed to precise dimensions, ensuring uniformity.

- Collation and Sorting: Pages are organized into signatures, and the correct order is verified.

- Folding and Creasing: Pages are folded into signatures, and creasing ensures smooth binding.

2. Sewing:

- Signature Assembly: Signatures, or groups of folded pages, are arranged correctly for sewing.

- Sewing Process: Smyth Sewn Binding involves a specialized stitching technique that securely binds the pages together while maintaining flexibility.

- Quality Control During Sewing: Continuous checks ensure no missed stitches, and the thread tension remains consistent.

3. Gluing (if Needed):

- Application of Adhesive: If adhesive is required for additional strength or to attach the cover, it is applied evenly and precisely.

- Drying and Curing: The adhesive can dry and cure for a strong bond.

4. Trimming and Finishing:

- Final Trimming of Pages: The edges of the pages are trimmed to achieve precise dimensions.

- Cover Attachment (if Applicable): If a cover is used, it is attached to the book block using appropriate techniques.

- Book Blocking and Pressing: The book is subjected to pressing to ensure the flatness and alignment of the pages.

Quality Control and Inspection

- Checking for Sewing Defects: Inspection is done to identify any loose stitches or misaligned signatures.

- Ensuring Proper Alignment of Pages: The correct page order is verified, and any misalignment issues are corrected.

- Cover Attachment Inspection (if Applicable): The adhesion of the cover and its alignment are checked.

- Assessing Overall Binding Quality: The entire binding is evaluated for integrity and a professional finish.

- Corrective Measures and Adjustments: Any identified binding issues are addressed, and necessary adjustments are made to maintain the quality.

More Bookbinding Tips-Exploring Various Bookbinding Techniques: A Comprehensive Guide

How to Choose the Right Smyth Sewn Binding Service?

When it comes to selecting the exemplary Smyth Sewn Binding service for your publication needs, several factors should be taken into consideration:

Factors to Consider:

- Experience and Expertise: Look for a binding service provider with a proven track record and extensive experience in Smyth Sewn Binding. High quality results are more likely from an experienced team.

- Technology and Equipment: Check if the service provider uses modern and efficient binding machinery and technology. Up-to-date equipment can enhance the quality and efficiency of the critical process.

- Customization Options: Determine whether the service provider offers customization options for your project requirements. This includes choices for paper, cover materials, and finishing touches.

- Quality Control: Inquire about the service provider’s quality control measures. A commitment to quality assurance ensures that your publications meet the highest standards.

- Turnaround Time: Consider the turnaround time for your project. Ensure that the service provider can meet your deadlines without compromising on quality.

- References and Reviews: Review past clients’ reviews and references to gauge the service provider’s reputation and customer satisfaction.

- Cost: While cost is a factor, it should not be the sole determining factor. Assess the overall value provided by the service, including quality and reliability.

Collaboration with Binding Companies

Establishing a collaborative relationship with a trusted binding company can be highly advantageous if you are a book printing manufacturer or a publisher looking for Smyth Sewn Binding services. Collaborating with a crucial company can provide you with the expertise and capacity needed to meet the critical requirements of your projects, whether they involve book printing services or other publications.

By forging strong partnerships with binding companies specializing in Smyth Sewn Binding, you can streamline your production process and ensure consistent, high-quality results for your clients.

Frequently Asked Questions

1. What is the difference between Smyth Sewn Binding and Perfect Binding?

Smyth Sewn Binding and perfect binding are two distinct binding methods with different characteristics:

- Smyth Sewn Binding involves sewing together folded sheets or signatures. It offers exceptional durability, allows books to lay flat when opened, and is suitable for various types of publications. It is commonly used for high-quality books.

- On the other hand, perfect binding involves gluing individual pages’ spines to a cover. While it is cost-effective, perfect-bound books may not lay flat when opened, and the adhesive may deteriorate over time, making it less durable than Smyth Sewn Binding.

2. Is Smyth Sewn Binding suitable for small-batch production?

Yes, Smyth Sewn Binding is suitable for large-scale and small-batch production. Its versatility makes it ideal for producing a limited number of books or publications while maintaining the same high-quality standards. Whether you need a few copies or a large print run, Smyth Sewn Binding ensures durability and a professional finish.

3. What are the pricing factors for Smyth Sewn Binding?

The cost of Smyth Sewn Binding depends on several factors, including:

- The size and page count of the publication.

- The type and quality of paper or materials used.

- Customization options, such as cover materials and finishes.

- The complexity of the binding process.

- Quantity and production volume.

Request a quote from your chosen binding service provider, who can provide a detailed estimate based on your specific project requirements.

4. How to protect Smyth Sewn Binding books from damage?

To protect Smyth Sewn Binding books from damage and ensure their longevity, consider the following tips:

- Store books in a cool, dry, and well-ventilated environment to prevent moisture damage.

- Avoid exposing readers to direct sunlight, as it can fade covers and damaged pages.

- Handle books with clean hands to avoid transferring oils and dirt to the pages.

- Use book covers or dust jackets to shield books from dust and debris.

- Store books upright to prevent warping or bending of the bodies and pages.

Proper care and maintenance can extend the life of Smyth Sewn Binding books and keep them in excellent condition for years to come.

Cost and Time Considerations

Smyth Sewn Binding’s Cost Range

The cost of Smyth Sewn Binding can vary depending on the complexity of your project and your specific requirements. Factors that influence the cost include:

- Book Size and Page Count: Larger books or publications with more pages may require more materials and labor, affecting the overall cost.

- Paper Quality and Type: Choosing paper or materials can significantly impact the cost. Premium or specialty papers may come at a higher price.

- Customization: If you opt for custom cover materials, finishes, or additional embellishments, these choices can add to the overall cost.

- Quantity: The volume of books or publications you need will influence the cost per unit. Typically, larger print runs result in lower unit costs.

Obtaining quotes from Smyth Sewn Binding service providers is advisable, as they can provide you with a precise cost estimate based on your project’s specifications.

Production Timeline

The production timeline for Smyth Sewn Binding projects can vary depending on several factors:

- Project Complexity: More complex projects may require additional customization and quality control time.

- Quantity: Larger print runs may take longer to complete due to the increased volume of binding required.

- Customization: If your project involves unique cover designs or special finishes, additional time may be needed for these customizations.

- Service Provider’s Capacity: The availability and workload of your chosen service provider can impact the production timeline. Discussing your project’s timeline requirements with them in advance is essential.

To ensure your project is completed within your desired timeframe, clearly communicating your deadlines with your Smyth Sewn Binding service provider is advisable. This will allow them to plan and schedule the production accordingly.

Conclusion

Smyth Sewn Binding is a time-tested and reliable method for creating durable, high-quality publications. Whether you are a book printing manufacturer seeking excellence in your products or a publisher aiming to provide your readers with top-notch publications, Smyth Sewn Binding services can elevate your offerings.

By understanding the advantages, processes, and considerations of Smyth Sewn Binding, you can make informed decisions for your publishing projects. Partnering with experienced binding service providers ensures that your publications meet the highest standards of quality and craftsmanship.

If you have any further questions or would like to explore Smyth Sewn Binding services, feel free to contact reputable binding companies specializing in this technique. They can provide expert guidance and solutions tailored to your unique needs.