Introduction

In the dynamic world of book publishing, the choice of a book printing factory plays a pivotal role in transforming manuscripts into compelling, physical entities. This guide delves into the complexities of book printing, aiming to clarify prevalent doubts and provide insights from the perspective of book printing manufacturers. Whether you’re an independent author or a publishing house, understanding the intricacies of printing technologies is crucial for making informed decisions that resonate with your audience and uphold industry standards.

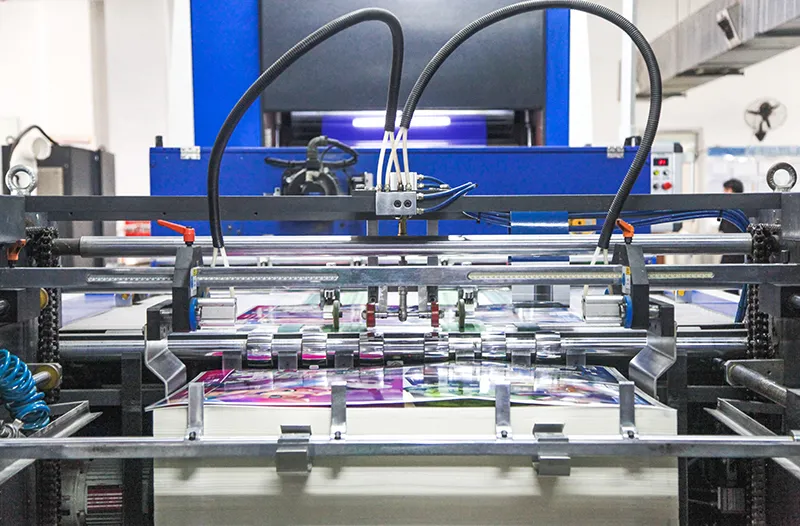

Overview of Printing Technologies

Digital Printing

Digital printing, a preferred method for many modern book printing factories, offers significant advantages, particularly regarding flexibility and speed. Ideal for short runs and on-demand printing, it allows book printing manufacturers to produce books without the need for extensive setup processes. However, while digital printing excels in efficiency, it may need to be improved in color range and durability compared to traditional methods.

Offset Printing

On the other hand, many book printing factories turn to offset printing for large-volume orders. Renowned for its exceptional color accuracy and quality, it remains a staple in the industry. Book printing manufacturers often recommend compensation for projects where color fidelity and print longevity are paramount. Its drawback, however, lies in its higher setup costs and longer turnaround times, making it less ideal for small print runs.

Digital vs. Offset

Choosing between digital and offset printing depends mainly on your project’s scale, budget, and quality requirements. While digital printing offers agility and cost-effectiveness for smaller quantities, offset printing stands out for its superior quality in larger, more color-intensive projects. The decision ultimately rests on your publication’s specific needs and goals, a choice that a knowledgeable book printing factory can guide you through.

Paper and Ink Selection

A crucial decision in the book printing process, often guided by the expertise of a book printing factory, is the selection of paper and ink. This choice directly impacts not only the aesthetic appeal but also the tactile experience of the reader.

Types of Paper

The type of paper used can vary widely, from glossy, coated documents that bring out vivid colors and images to uncoated, matte papers preferred for their readability and classic feel. Book printing factories often advise on the best paper type based on the book’s genre, purpose, and design.

Ink Choices

Similarly, the choice of ink plays a significant role. Standard inks are widely used and are effective for most purposes. However, premium inks can offer deeper colors and more excellent durability, a feature often suggested by book printing manufacturers for high-quality art books or photography volumes. The right combination of paper and ink can elevate a text from a mere collection of pages to a work of art.

Color Management in Printing

In book printing, color management is a critical component, often meticulously handled by seasoned book printing factories. This process ensures that the colors in the final product faithfully represent the original design.

Importance of Color Accuracy

For authors and publishers, the accurate reproduction of colors is essential, especially for books with photographic content or intricate illustrations. Book printing manufacturers employ advanced color management systems to maintain consistency and accuracy across all printed copies.

Techniques

Fundamental techniques in color management include calibrating printers and monitors, using color profiles that match the printing process, and conducting regular quality checks. This level of precision in color reproduction is a hallmark of leading book printing factories, distinguishing their products in a competitive market.

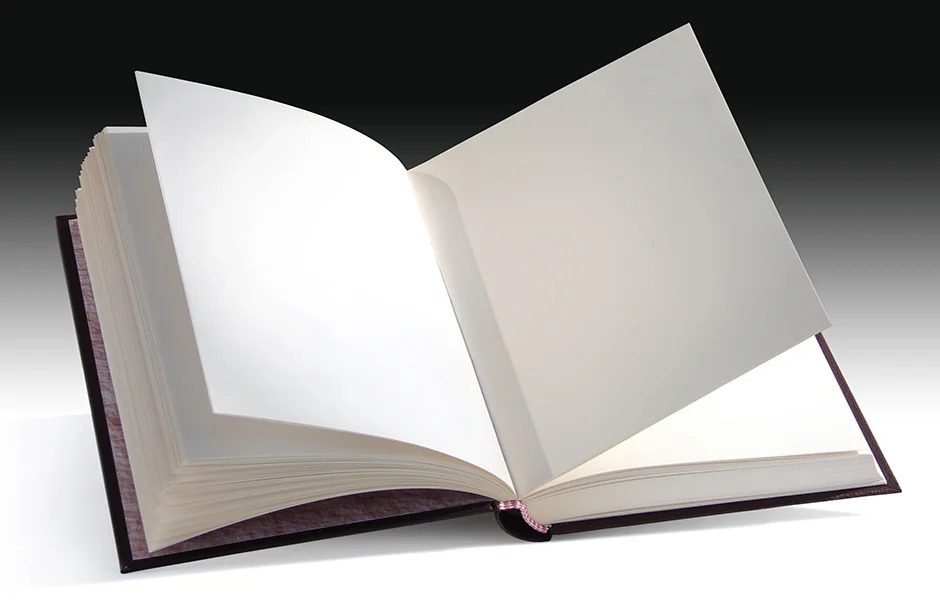

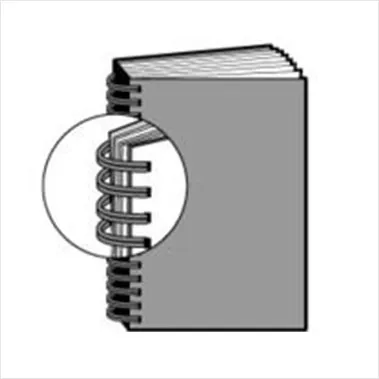

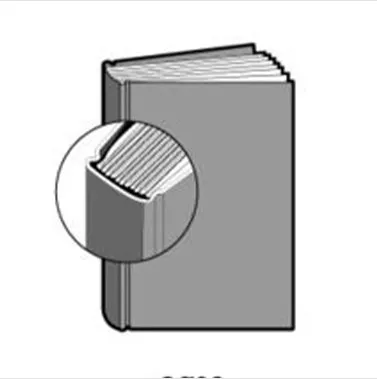

Binding and Finishing Techniques

Once printing is complete, the next critical phase managed by book printing factories is binding and applying the finishing touches. This stage is not just about assembling pages; it’s an art that adds to the book’s durability and aesthetic appeal.

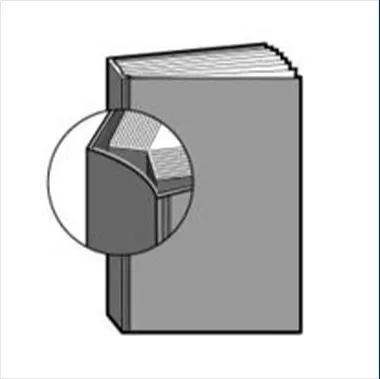

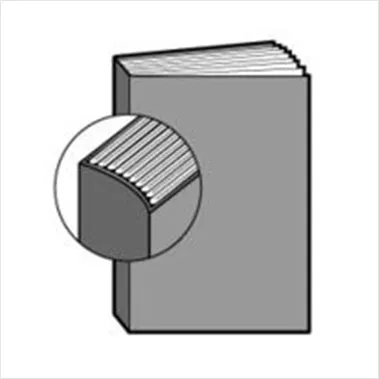

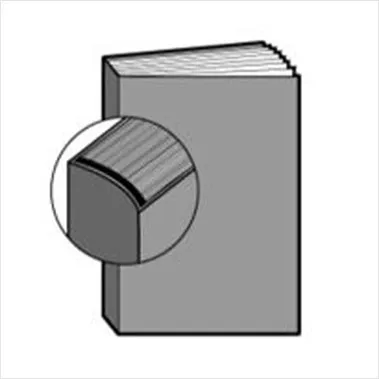

Various Binding Methods

The choice of binding method depends on the book’s purpose and design. Common types include perfect binding, widely used for novels and non-fiction works; saddle stitching for smaller booklets and magazines; and hardcover binding for premium editions. Expert book printing manufacturers can advise on the best binding method for your project, considering the book’s size, page count, and intended use.

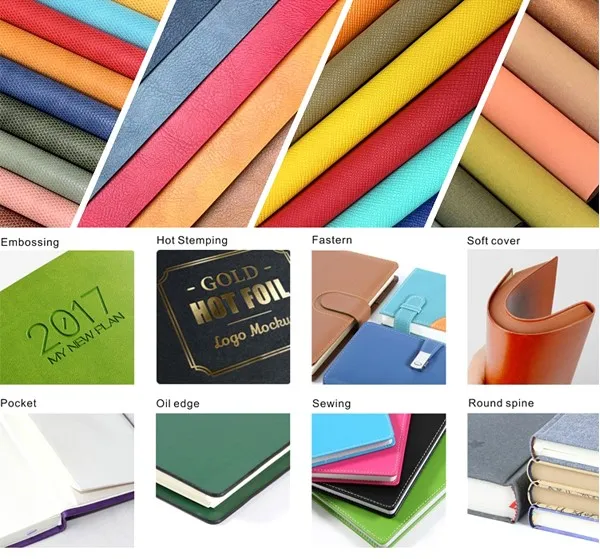

Finishing Touches

Finishing touches can significantly enhance a book’s look and feel. Options include glossy or matte laminations, embossing, foil stamping, and varnishes. These details, often recommended and executed by skilled book printing factories, can turn a simple printed book into a tactile and visual experience, leaving a lasting impression on readers.

Cost Management and Budgeting

An essential aspect often navigated with the assistance of book printing factories is the management of costs and budgeting. Balancing quality with affordability is critical to successful book production.

Cost-Effective Printing

To achieve cost-effectiveness, it’s crucial to understand the various factors that impact printing costs. These include printing technology, paper type, ink, binding, and finishing options. Book printing manufacturers can provide valuable insights into cost-saving practices without compromising quality, such as optimizing page layouts to reduce waste or selecting the most suitable printing method for the project’s scale.

Bulk Printing vs. Print-on-Demand

Bulk printing, typically more cost-effective for large runs, can reduce the unit cost significantly. However, it requires a substantial upfront investment and can lead to excess inventory. Print-on-demand, offered by some book printing factories, allows for printing smaller quantities as needed, reducing initial costs and storage needs. This method is particularly beneficial for independent authors or publishers who face budget constraints or uncertain demand.

Sustainability in Printing

Sustainability in printing is becoming increasingly important, and many book printing factories are adopting eco-friendly practices. This includes using recycled or sustainably sourced paper, eco-friendly inks, and energy-efficient printing technologies. Choosing a book printing manufacturer that prioritizes sustainability helps reduce the environmental impact and appeals to environmentally conscious readers.

Common Pitfalls and How to Avoid Them

Navigating the book printing process can be fraught with challenges. Awareness of common pitfalls and partnering with an experienced book printing factory can make a significant difference.

Identifying Potential Issues

Some frequent issues include miscommunication about project specifications, underestimating timelines, and overlooking proofing processes. These can lead to delays, unexpected costs, and disappointing final products.

Solutions and Best Practices

Clear and continuous communication with your book printing manufacturer is essential to avoid these pitfalls. Ensure that all specifications, from paper quality to binding requirements, are thoroughly discussed and agreed upon. Additionally, allocate sufficient time for proofing and adjustments. Emphasizing the importance of quality checks at every stage of the printing process is crucial for a successful outcome.

Conclusion

The journey of transforming a manuscript into a book is both intricate and rewarding. By understanding the various elements of book printing, from technology and materials to binding and sustainability, and by avoiding common pitfalls, authors and publishers can ensure their stories are presented in the best possible way. Collaborating with a knowledgeable book printing factory is pivotal in turning your literary vision into a tangible reality that captivates readers.